Motorcycle Parts New Zealand Specialists for Dummies

Table of ContentsThe Definitive Guide to Motorcycle Parts New Zealand SpecialistsThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists Can Be Fun For EveryoneMotorcycle Parts New Zealand Specialists Fundamentals ExplainedAn Unbiased View of Motorcycle Parts New Zealand SpecialistsThe Buzz on Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals Explained

So, connect to one of our professionals today.CNC machining technology is promptly ending up being the focal point of several production procedures around the world as a straight outcome of its numerous advantages over other techniques. Furthermore, the industries that make bikes have hopped on board with this trend. One of the most cutting-edge firms are now creating their engine components and wheels making use of machining techniques originally created for motorbike components.

You might be questioning why we make use of. Now that we have your attention let us clarify the rationale behind this modern-day advancement in the motorcycle production market.

Not known Facts About Motorcycle Parts New Zealand Specialists

In addition, you have full control over the appearance of the elements, even down to the min details. Occasionally, motorcyclists may decide to spruce up their experience by installing aftermarket elements or changing the bike's makeover.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

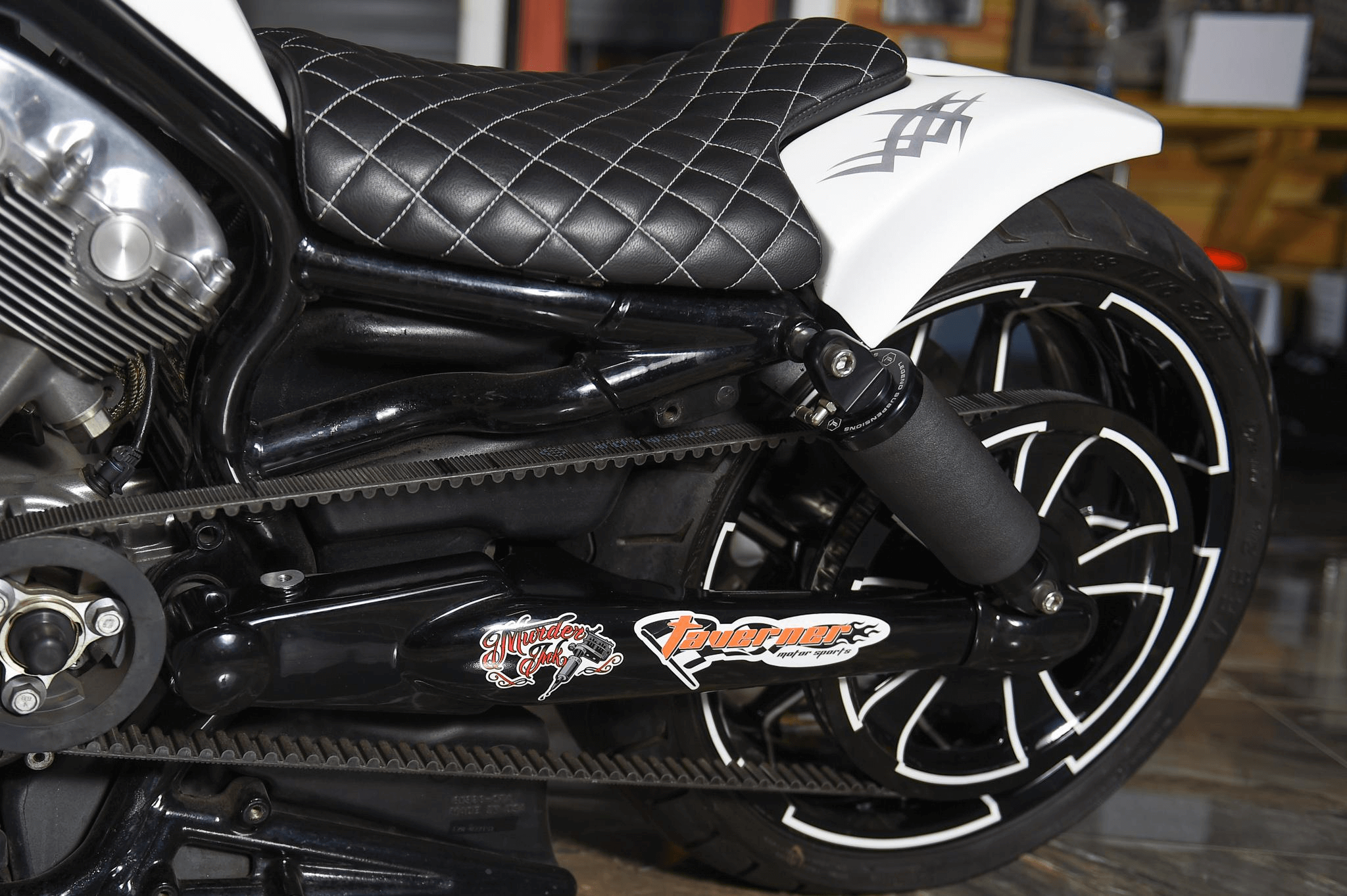

CNC machining may be used to make almost all of a motorcycle's metal and plastic components. To continue, we'll go over several machined components for bikes. In comparison to those on cars, wheels on motorbikes often tend to be extra apparent. As a result, the bike's looks may be boosted with the appropriate modification of these wheels.

Milling treatments are made use of to get the wanted degree of wheel personalization. Another facet of the motorcycle that might be individualized is the tires.

Motorcycle Parts New Zealand Specialists - An Overview

When it pertains to a car (or a motorcycle), one of the most crucial element is the engine. Several people mention it as the "heart" of the auto. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and need layouts with a high level of precision.

Illumination is an additional facility facet of modification. Usage only high-grade products, nevertheless, given that these lights are important for the safety of motorcyclists and various other drivers or individuals on the road, particularly during the night. Motorcycle fronts lights have 3 primary parts: the bulb, or light, the lens, and the housing. In particular, we tailor the lens and the housing.

Milling procedures with a flawless surface would certainly result in the lenses having a reflective quality that is comparable to that of a mirror. The cover, on the various other hand, is not composed of breakable products; instead, it is created out of challenging polymers that can be machined into more intricate patterns.

The 6-Minute Rule for Motorcycle Parts New Zealand Specialists

Bike suppliers often cast these components, however just for the manufacturing of bespoke components. Machining on five axes in today's world is the ways by which any kind of style form may be realized.

Pick Runsom for image source your personalized bike parts! We have the capacity to fabricate complex and fashionable components making your motorbike unparalleled.

Right here are a few examples of steels often used in bike component machining. Aluminum is the key product utilized by firms specializing in producing customized bike parts to create the majority of these parts. In the past, we would certainly construct our engines out of cast iron. On the other hand, light weight aluminum is swiftly becoming the material of selection, partially as a result of the fact that it is much more light-weight.

Zinc refers to another steel that is really light in weight and has excellent machining high qualities because of its high mechanical stamina. This material might be formed into almost any kind of form and keeps its measurements well. Also mission-critical parts that need a high level of precision might profit from their usage.

Fascination About Motorcycle Parts New Zealand Specialists

Another metal that sees hefty use in the production of CNC-customized components is magnesium. It is amongst the lightest steels that are currently obtainable and has exceptional machinability attributes and strength commensurate with its low weight. One of the disadvantages of magnesium is that its dirt might easily ignite.

Their most typical use in producing different motorcycle parts is bolts, such as screws and screws. Their reduced sensitivity to oxidation and rust makes them excellent for this use.

Not known Factual Statements About Motorcycle Parts New Zealand Specialists

It appears that CNC turning and grating are the fundamental processes. In enhancement, it calls for maintaining bars of product, most often plastic or metal, in placement and then turning a cutting device to remove sections of the material as the material is transformed.

These approaches are just as essential and produce elements with high accuracy and constant top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface coating" describes post-processes after the first machining stage. Motorcycle Parts New Zealand Specialists. The procedures assist boost the general top quality of the machined motorcycle elements. Below are the quick introduction, pros and disadvantages of 5 surface therapy methods.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone